Product Overview

Kersten KM 16545 M Front Mounted Mecahnical PTO Sweeper Attachment for tractor from 12- 40hp

The Kersten KM 16545 M is a mechanically PTO-driven 165cm front sweeper offering high performance in a lightweight, versatile design. It features a large 5-row poly spiral brush for efficient debris removal and a pendulum suspension system for protection over rough terrain. The mechanical angling 26° allows left and right swivel for enhanced maneuverability in tight spaces. Sweeping height is adjustable with individually set gauge wheels for precise positioning. Compatible with various vehicles, including John Deere X-series, Kubota B1220, and Kubota RTV. Ideal for low-speed, high-torque tasks such as block paving soil removal, with customization options for lighter material applications like snow.

165 cm

45 cm

26°

146 kg

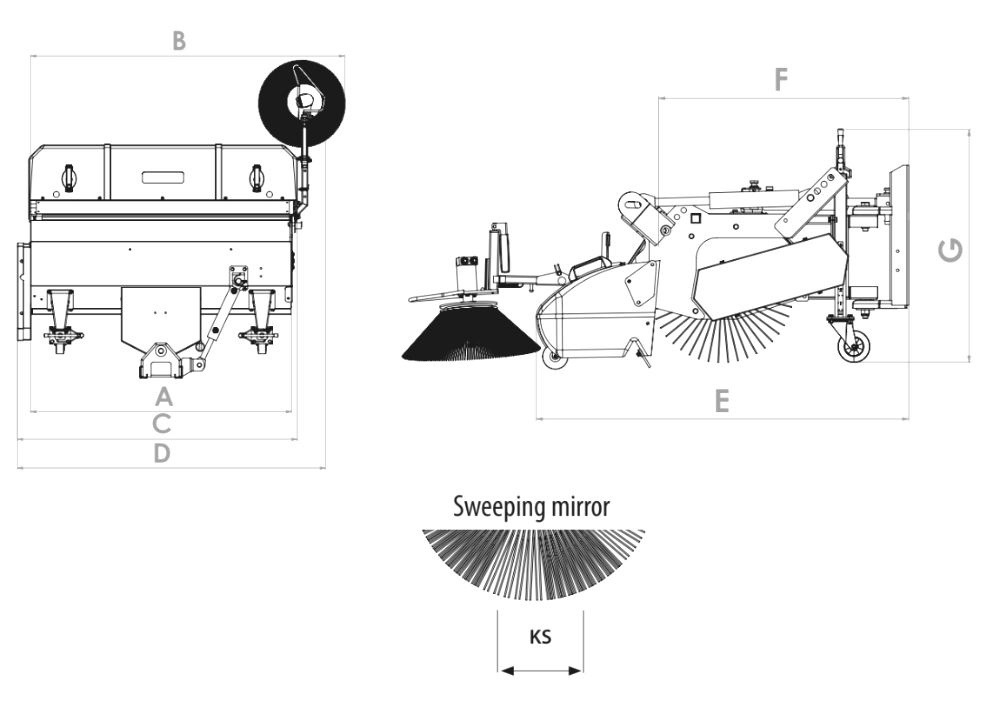

Technical Specifications

| Machine Specification | Details |

|---|---|

| Overall Machine Width | 175 cm |

| Overall Machine Length | 79 cm |

| Machine Height | 73 cm |

| Working Width | 165 cm |

| Brush Diameter | 45 cm |

| Swivel Angle | 26° |

| Weight | 146 kg |

| Height Adjustment | 2 Heavy-Duty Running Wheels (135 x 40 mm) |

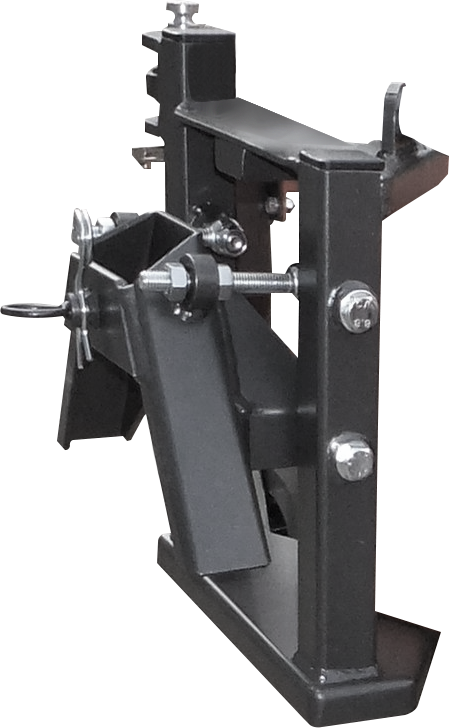

| Mounting | Attachment Frame ABR 45 Required |

| Optional Accessories | Gully Brushes, Collector Box and Front Brush Guard |

Features

- Mechanically PTO Driven 165cm working width sweeper attachments

- An inboard variable speed motor, with constant tension duplex drive chain allows greater power to the brush and negates chain slippage.

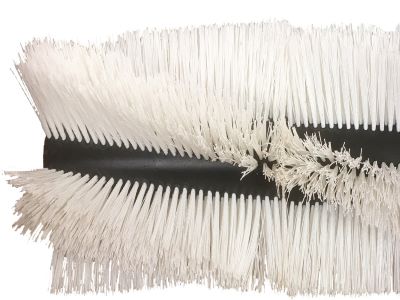

- Including 2 section; 5 row poly sweeper brush ensures effective debris removal on hard and artificial surfaces.

- Compact, robust steel frame for long-lasting performance in demanding environments.

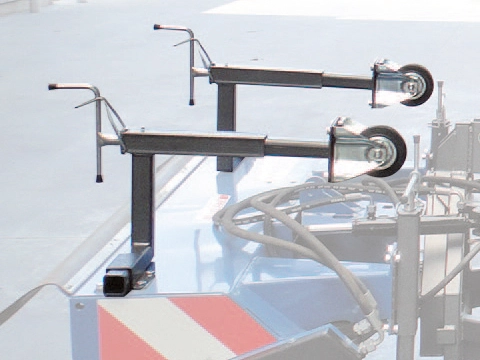

- Two heavy-duty 135 x 40 mm wheels allow easy adjustment for optimal brush positioning.

- Mecahnical left and right swivel directly from the driver’s seat for maneuverability.

- Includes garage stand for easy storage

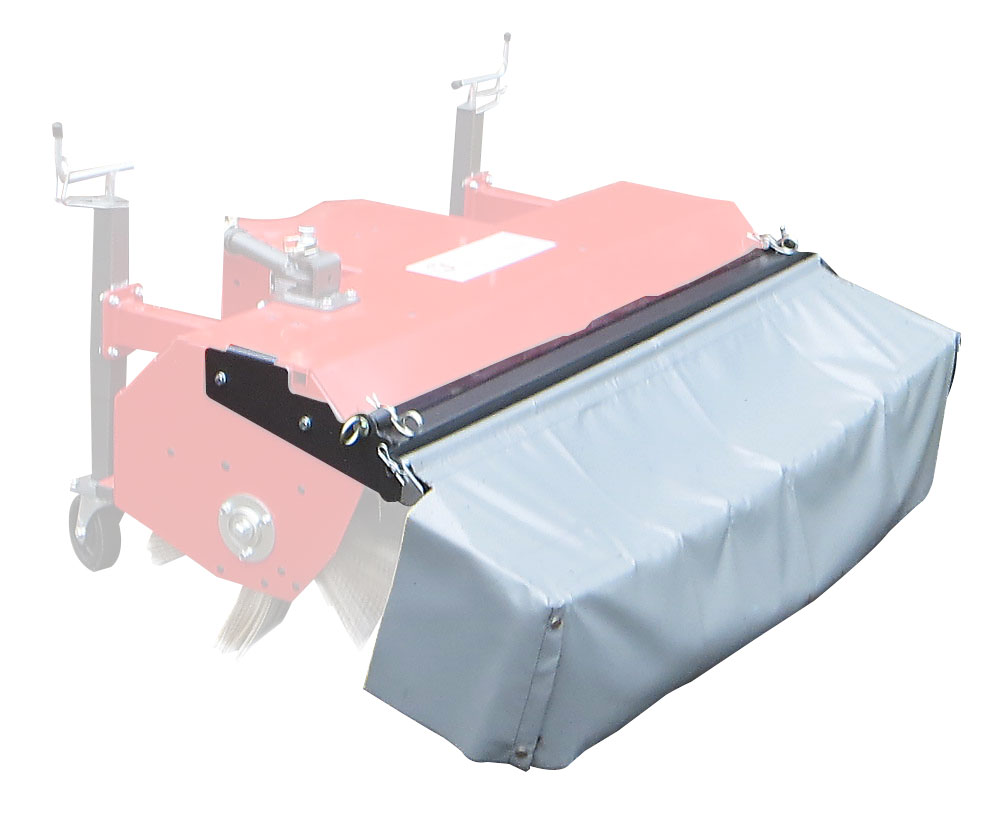

- Optional Accessories: Gully brushes, front brush guard and collector box

.png)

Optional Accessories

Consumables

Compatible Bracket

ABR Brackets is required for mounting the attachment onto various types of linkage

Product Applications

Sweeping on Hard Surfaces

When organic debris covers a hard surface it looks unsightly, but it also blocks drainage channels, which leads to surface water. Over time the material will decompose producing soil. Opportunistic weeds can use this soil as a platform to grow on the surface, which can cause damage over time. So it is really important to keep the surface swept and to remove the material.

Sweeping on Artificial Surfaces

In addition to the normal problems we face maintaining hard surfaces; artificial surfaces have infill, which gets compacted and also migrates around the surface. This infill can be de-compacted with a sweeper allowing the surface to drain properly. The sweeper will also even out the distribution of infill and stand up the grass, making the surface much nicer to use.

.jpg)

KM 45 Front Mounted Sweeper Case Studies

Instruction Manual and Spare Parts List

When deciding between a sweeper and a weed brush for asphalt and tarmac maintenance, consider the specific issues you're facing:

- Sweeper: Ideal for removing loose debris, leaves, and dirt that accumulate on the surface and in gullies. A powered sweeper with a collector box is effective in preventing detritus buildup, which can obstruct drainage and lead to moss and weed growth. It is also useful for cleaning edges and keeping pavements clear. Our pedestrian sweepers also come with a de-moss brush, which helps remove moss and algae that may have started to grow on the surface.

- Weed Brush: Best for tackling established weeds and moss that have penetrated the surface. A weed brush can effectively remove these invasive plants, which can cause surface cracks and deterioration over time. It’s particularly useful in areas where weeds have started to penetrate the tarmac, causing damage.

Recommendation: For comprehensive maintenance, use a combination of both tools. Start with a weed brush to address any existing moss and weeds, then follow up with a sweeper to clear the surface and prevent further issues. This dual approach ensures both removal of vegetation and effective debris management, maintaining the integrity and appearance of your asphalt or tarmac surfaces.

Yes, the Gully Brush is compatible with most sweepers, enhancing their ability to achieve clean, crisp edges along paths. This brush not only maintains a visually appealing site but also excels in reaching the corners of kerbs to remove debris. Effective debris management is crucial for preventing weed growth, making the gully brush an essential tool for maintaining a well-kept, weed-free area.

Explore our range of sweepers to find the compatible gully brush for your needs.

Regularly removing soil and heavy debris is essential for effective grounds maintenance to ensure the longevity and safety of hard surfaces such as asphalt, tarmac, and block paving. Accumulated soil and debris can lead to several issues:

- Surface Degradation: Soil and debris, when left unmanaged, can contribute to surface damage. Organic material decomposes and forms a layer of detritus that can compromise the structural integrity of pavements and roads.

- Weed and Moss Growth: Moisture trapped by debris promotes the growth of weeds and moss. This not only deteriorates the surface but also creates hazards for pedestrians and vehicles. Regular removal prevents these issues from taking hold.

- Drainage Problems: Debris accumulation around drainage edges and kerb lines can block water flow, leading to flooding and further surface damage. Maintaining clear drainage areas is critical for preventing water-related problems.

- Enhanced Safety: Removing debris prevents slippery conditions, reducing the risk of accidents. It ensures that walkways and roadways remain safe for users, especially in high-traffic or frequently used areas.

- Cost Efficiency: Regular maintenance reduces the need for costly repairs by addressing issues before they escalate. It helps keep the surface in good condition, minimizing long-term expenses associated with extensive repairs or replacements.

For effective soil and debris management, tools like sweepers and weed brushes are invaluable. They help efficiently clear and maintain hard surfaces, ensuring a clean, safe, and durable environment.

Weeds thrive on tarmac and asphalt surfaces when detritus, such as leaves and twigs, accumulates in gullies and along pavement edges. This buildup creates a medium for weeds to grow. Once weeds establish themselves in the debris, their roots can penetrate the surface, leading to cracks and further surface damage. Over time, the cracks widen, causing the surface to crumble and form potholes. Regular use of a gully brush and powered sweeper with a collector box is essential for clearing debris from edges and gullies, preventing detritus from rotting and providing a breeding ground for weeds. This helps maintain the integrity of the surface and prevents costly damage.

To prevent moss and algae growth, ensure regular sweeping to remove organic debris and detritus. Prune nearby trees and hedges to reduce leaf and twig accumulation. Maintain proper drainage by addressing any issues with sand displacement or compaction.

Kersten weed brushes and powered sweepers are essential tools for maintaining block paving surfaces. The Kersten weed brush effectively agitates and lifts moss from between the blocks, preventing moisture retention and surface damage. Complemented by the Kersten sweeper, which efficiently collects debris and redistributes sand into gaps, this combination ensures optimal drainage and surface stability. Together, these tools help maintain the appearance, durability, and safety of your block paving, extending its lifespan and reducing the risk of moss-related issues.

For kerb edges that are heavily compacted with weeds and debris, a weed brush is your best tool. Its strong bristles can effectively break through dense and stubborn material, making it ideal for removing compacted detritus and weeds from tight spots. The weed brush excels in heavy-duty conditions where traditional sweepers might be less effective. Use it to slide out debris from kerb edges and clear buildup, especially in areas with significant compacted soil and detritus.

For general maintenance of kerb edges, employing a sweeper with a gully brush attachment can enhance cleanliness and efficiency. The sweeper will handle loose debris, while the gully brush helps clear material trapped in the edges, ensuring crisp and well-maintained kerb lines. This combination helps create clean, defined edges and keeps your surfaces in good condition. For more details on these tools, check out our weed brush, sweeper, and gully brush product pages.

To control dust on asphalt surfaces, adjust your sweeper's brush speed to a slower setting to minimize dust dispersal. Spraying water directly onto the brush or the surface helps bind the dust, making it heavier and easier to collect. Kersten sweepers are available with dust suppression kits can efficiently handle dust without spreading it around.

A dust suppression kit sprays water directly onto the brush of a sweeper and surface. This technique helps bind dust particles, making them heavier and easier to collect. By reducing the amount of dust that becomes airborne, these kits help maintain cleaner surfaces and improve air quality.

For hard-to-reach areas, use a pedestrian two wheel tractor such as K-series or UBS-series with dust suppression kit. Adjust the brush speed to a slower setting and apply water to the brush to control dust effectively. A debris guard can also help manage dust in confined spaces.

The Gully Brush is a specialized attachment for sweepers, expertly designed to manage debris in challenging areas such as edges, gullies, and kerbsides. It efficiently pulls dirt, leaves, and other debris from these hard-to-reach spots into the path of the main sweeper brush. Once in the sweeper brush’s path, the debris is collected by the sweeper and deposited into the collector box, ensuring a comprehensive clean and a polished finish.

The frequency of replacement depends on the amount of usage and the type of debris you're dealing with. Regular inspection is recommended, and brushes should be replaced as soon as you notice signs of wear, such as reduced cleaning performance or uneven bristle wear.

Road sweeping in the UK is governed primarily by the Environmental Protection Act 1990 (EPA 1990) and the Highways Act 1980, which place a statutory duty on local authorities and the Secretary of State (via National Highways) to keep public areas and highways clean.

Key Legislation and Responsibilities

Environmental Protection Act 1990: Section 89(1) and (2) of this Act places a duty on 'duty bodies' (primarily local authorities) to ensure public spaces and highways are, as far as practicable, kept clear of litter and refuse.

Highways Act 1980: This Act includes provisions that make it an offence to deposit anything on a highway that might obstruct its use, create a danger, or cause injury.

Code of Practice on Litter and Refuse: This document, issued under the EPA 1990, provides practical guidance and sets standards for cleanliness (Grades A-D) and expected response times for cleaning different areas.

Clean Neighbourhoods and Environment Act 2005: This Act strengthened existing legislation related to street cleaning and environmental quality.

The Poly Spiral Roller Brush and De-Moss Brush are designed for different cleaning tasks and may not always be interchangeable. The Poly Spiral Roller Brush is ideal for general debris sweeping, such as dust, leaves, soil, and small rocks.

On the other hand, the De-Moss Brush is specifically engineered for tackling stubborn moss, especially in damp or shaded areas. While both brushes may perform similarly on surfaces like tarmac, the Poly Spiral Roller Brush may be less effective on thick moss, and the De-Moss Brush might not be the best choice for fine particles like dust.

Choose the brush that best fits your specific cleaning needs to ensure optimal performance.

Replacing the brush on your Kersten Brush is crucial for maintaining peak performance and efficiency. Over time, the brush bristles wear down from regular use, which can diminish their cleaning effectiveness and potentially damage the surfaces being cleaned. By replacing the brush, you ensure continued high performance in removing debris, moss, and tough dirt. Regular brush replacement also prevents equipment damage and guarantees consistent, reliable cleaning results.

The frequency of replacement depends on the amount of usage and the type of debris you're dealing with. Regular inspection is recommended, and brushes should be replaced as soon as you notice signs of wear, such as reduced cleaning performance or uneven bristle wear.

1892c3.jpg)

.png)

.webp)

.webp)