Kersten UK News

.jpg)

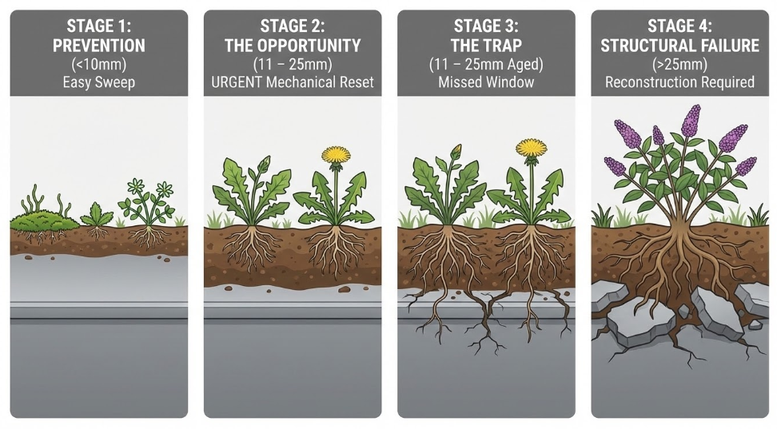

Sweeping, moss and weed control

A New Era of Stewardship: Why the Voluntary Initiative's Focus on Amenity is a Game-Changer

Honored to be the first VI Champion in Amenity. This marks a major institutional commitment to moving our sector beyond chemical reliance towards proactive, sustainable Integrated Pest Management.

.jpg)

(1).jpg)

.jpg)

(1) (1).jpg)

.jpg)

.jpg)