Product Overview

Lehner POLARO® L 'In body' mounted spreader

The Lehner POLARO® L is a robust 380-litre 'In body' mounted spreader, engineered for professional winter maintenance and year-round use. Designed for spreading salt, grit, sand, or fertiliser, it features dosing control and stepless working width adjustment directly from the cab. The corrosion-resistant stainless steel components and IP67-rated electrical system ensure outstanding durability across all vehicle types with a 12 V supply – including pickups, quads, sweepers, and utility vehicles.

380 L

0.8 – 6.0 m (12 m optional)

140 kg

1594 x 1199 x 884 mm

Technical Specifications

| Machine Specification | Details |

|---|---|

| Hopper Capacity | 380 L (approx. 500 kg of salt) |

| Spreading Width | 0.8 – 6.0 m (up to 12 m optional) |

| Spreading Area | approx. 25,000 m² |

| Hopper Dimensions (L/W/H) | 1594 x 1199 x 884 mm |

| Weight | 140 kg |

| Motor Power – Spreading Disc | 100 W |

| Motor Power – Conveyor | 250 W |

| Power Supply | 12 V (24 V operation via transformer optional) |

| Fuse | 30 A |

| Speed Range – Spreading Disc | 40 – 600 rpm |

| Speed Range – Conveyor | 2 – 54 rpm |

| Operating Temperature | -10 to +70 °C |

| Storage Temperature | -30 to +70 °C |

| Control | Control panel with memory keys (P1–P3), boost function, and diagnostics |

| Build Material | Stainless steel frame, disc and fixings; polyurethane hopper |

| Protection Class | IP67 (waterproof cables and motors) |

- Electric dosing and stepless spreading width adjustment via cab-mounted control panel

- Automatic vibrator start-up prevents clogging in damp conditions

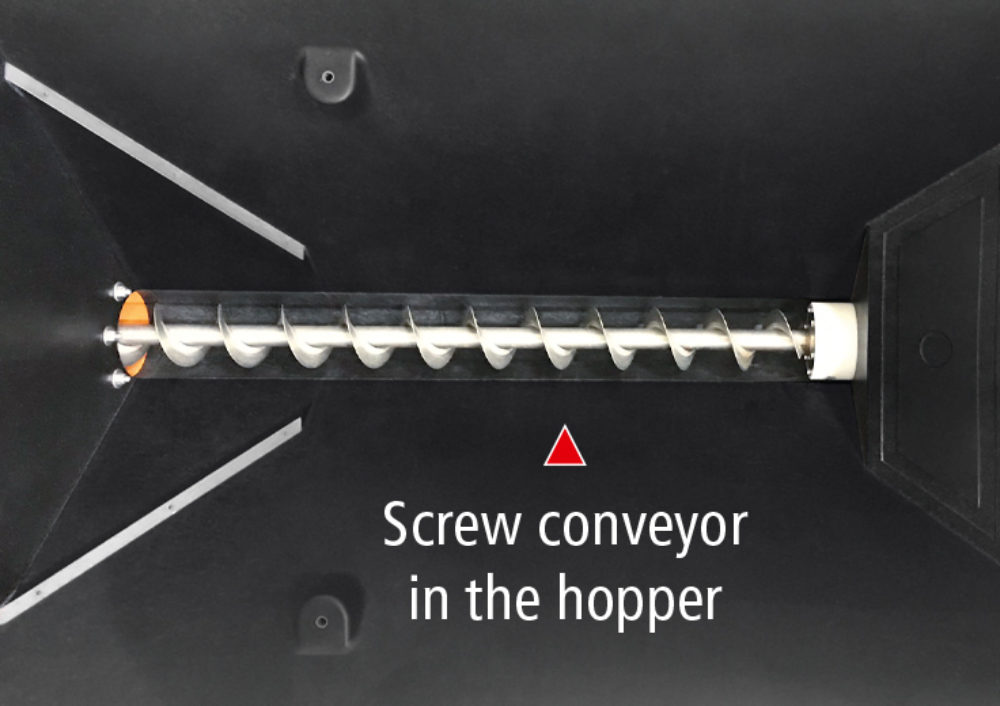

- Screw conveyor ensures constant material flow with speed control and breakaway protection

- Optional AUTO-DOSIS for vehicle speed-dependent dosing

- Built for 12 V vehicles including pickups, quads, sweepers, and utility vehicles

- All metal components are stainless steel for long service life and corrosion resistance

- Waterproof IP67 cables and gear motors for all-weather reliability

Applications

- Professional winter gritting of footpaths, estate roads, town centres, and car parks

- Versatile for summer use – spread fertiliser or sand with equal precision

Features

User-friendly operation with the POLARO® M/L/XL control panel

As well as infinitely adjusting the speed of the spreading disc to set the working width, you can also control all other functions centrally via the control panel, such as: Altering the screw speed to control the discharge rate, and boost function for briefly discharging larger quantities of spreading material when necessary (ice formation) Three memory keys (P1–3) for individual settings Automatic breakaway for screw conveyor Empty warning, residue emptying, service prompts, etc.

The materials are also streets ahead

All materials are designed for the particular challenges of winter work. So not only are all metal parts of non-rusting stainless steel as standard, but all cables and the individual gear motors are resistant to the ingress of dust and water (IP67). The hopper is made of temperature-resistant polyurethane that is completely impermeable to air and water, damps vibrations, and resists embrittlement.

Adjustable Spreading Pattern

The spreading disc can be manually positioned slightly more to the left or right, using two set screws. This way, material can be dispensed directly onto the neighbouring pavement or cycle path, for example, in parallel with gritting the road.

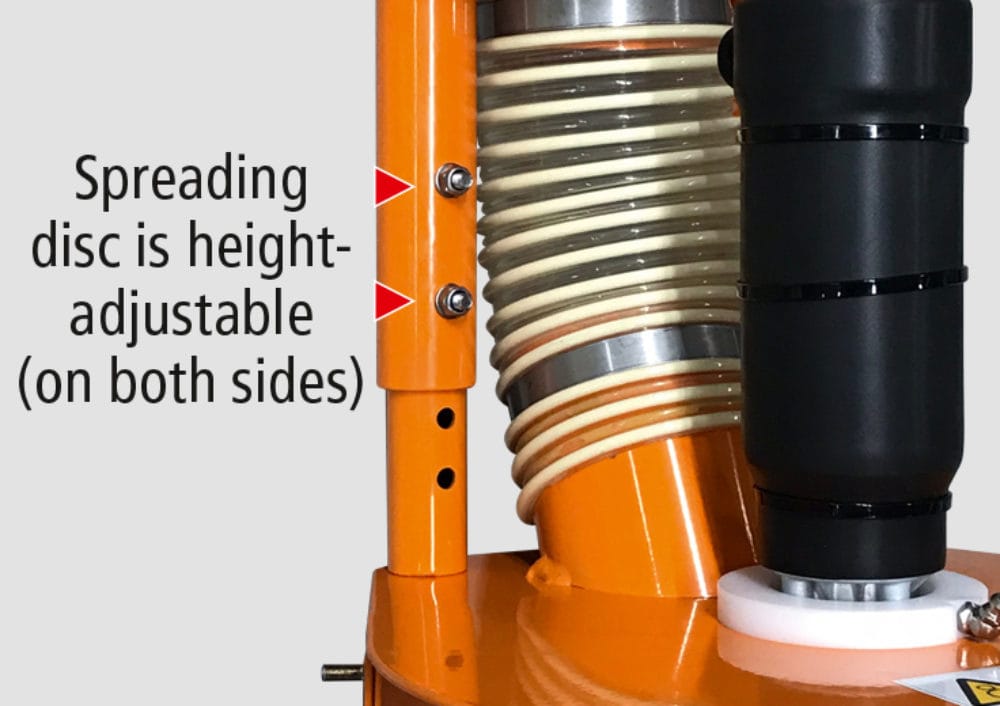

Height Adjustable Spinner Disc

To achieve the desired results regardless of carrier vehicle, the discharge height of the spreading disc (recommended: 0.40 – 0.80 m from the road surface) can be adjusted in the blink of an eye to suit different types of vehicle.

Vibrator with automatic start-up

The screw conveyor transports the material from the hopper to the spreader. If the flow is blocked, the vibrator – provided as standard – starts up automatically, breaking up the material in the hopper when necessary, so that it can continue to flow.

Optional Accessories cont.

Product Applications

Efficient Spreading of Sand, Salt, and Grit

Maintaining safe and accessible surfaces during icy or hazardous conditions is crucial. Spreader is the ideal tool for efficiently spreading sand, salt, or grit over large areas, ensuring pathways, parking lots, and roadways remain safe for both pedestrians and vehicles. Spreader significantly reduce the time and effort compared to manual spreading, allowing you to cover more ground with consistent results.

with ratchet.webp)