Electrifying your grounds maintenance equipment fleet

The switch to Electric grounds maintenance and landscaping equipment is perhaps happening even faster than the switch in cars.

Benefits of electric ground maintenance equipments

I come across many schools, councils and other organisations who have adopted a policy of only replacing equipment with electric alternatives if one exists. This might be driven primarily by environmental commitments, but in grounds maintenance there are many situations where the benefits of electric equipment are huge.

Working in noise sensitive situations

In many situations, noise is a huge factor. Petrol and Deisel Grounds maintenance equipment can make a large racket. Using this equipment around schools, or even urban areas can heavily restrict the times it can be used. Electric equipment lets you get on the job when ever you need.

A great example of this is weeding urban pavements. The gap between the cars and the pavement are often difficult to treat during the day, when the streets are much busier and more cars are parked over the pavements.

While a deisel operated weed killer would be too noisey to use by people's houses at night when the streets are less busy - An electric hot water weedkiller, pulled on an electric trolley is able to easily access the pavement and work away in virtual silence - allowing this job to be carried out by a night crew with no disturbance to sleeping residents. Likewise, weeding outside classrooms in a school can be done unobtrusively during lesson times.

https://kerstenuk.com/Eco-Weedkiller-Hot-Water-Weed-Management

It's also much better for the operators safety. There is no need to be wearing ear protectors, so the direct effect of that is huge, but it also means you can hear everything else that is going on in the environment, making you much more aware of potential risks.

Reducing Hand - Arm Vibration

Hand Arm Vibration is another issue which electric machines can overcome. Using a two wheel tractor all day can be a challenge for certain tasks, as the engine driven machines inevitably produce some level of vibration - despite efforts to reduce it. Weeding and cleaning pavements is a task requiring a lot of time behind the machine, as access and the sheer length of road and footpath networks make this job time consuming.

The Matador M-trac offers huge benefits to users in this regard, as it has no engine to produce vibrations. The vibrations generated by the attachment are far lower than those caused by the engines on these machines. In this case the battery power unit ensures your operators are comfortable using the machine all day long. The M-trac has battery capacity to cope with working for as long as you do.

https://kerstenuk.com/Matador-Electric-Walk-Behind-Multitool

Reducing Exhaust Emmissions and Air Polution with Electric Equipment

According to the California Air Resources Board in California - this year there will be more pollution from gas-powered gardening equipment than from cars, confirms Michael Benjamin, division chief.

With petrol equipment, the fumes are also difficult for the operators. Especially with hand held equipment, the fumes can be in very close proximity to the operator, but the same can be true with walk behind machines, especially in enclosed spaces where it is reflected off of nearby walls etc. This can cause headaches, as well as more serious problems, especially after extended exposure.

Battery equipment completely removes this hazard, with no direct exhaust fumes being emitted by the machines.

Reducing the Running Costs of your fleet

It's easy to get hung up on the increased upfront cost of battery powered equipment (in some situations), but this can often be mitigated well within the working life of the machine. Fuel costs are large in themselves compared to the price of charging electric equipment. Not to mention the reduction in maintenance, oils, replacement parts and the workshop hours associated with these.

Because of the noise and vibration reduction, you also allow your workers greater scope to use the machines, so you can get more productive time out of the machines every day.

Knock on effects of the right equipment can also reduce costs over time.

For example, when fitting a spreader and plough to an electric utility vehicle or even a petrol pickup; it is important to consider the power requirements of the attachments. Lehner spreaders for example, only draw about 30% of the current that other spreaders on the market use. This puts far less load on the batteries of the carrier vehicle, reducing electrical problems and power consumption. This gives you far more reliability and time on the job.

https://kerstenuk.com/Lehner-Polaro-Spreaders

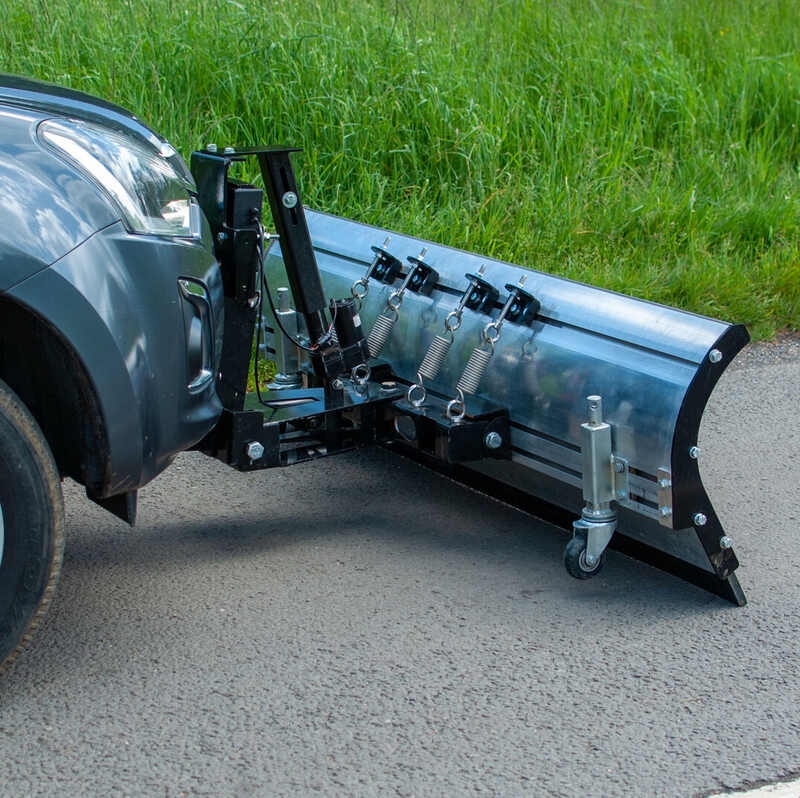

The weight of equipment is also a consideration when using electric vehicles. A heavier plough will increase the work the carrier vehicle must do, which affects fuel consumption and battery times. A light weight plough, such as the Faulkner Brothers 4x4 blade can make a big difference.

https://kerstenuk.com/Faulkner-Brothers-Snow-Ploughs-for-4x4s-and-Utility-Vehicles

No comments yet. Login to start a new discussion Start a new discussion