Hycut! Hybrid Mower Principles

So how is the Kersten Hycut hybrid mower a true Hybrid. Batteries Included......

The new Kersten Hycut Hybrid mower is powered from batteries!

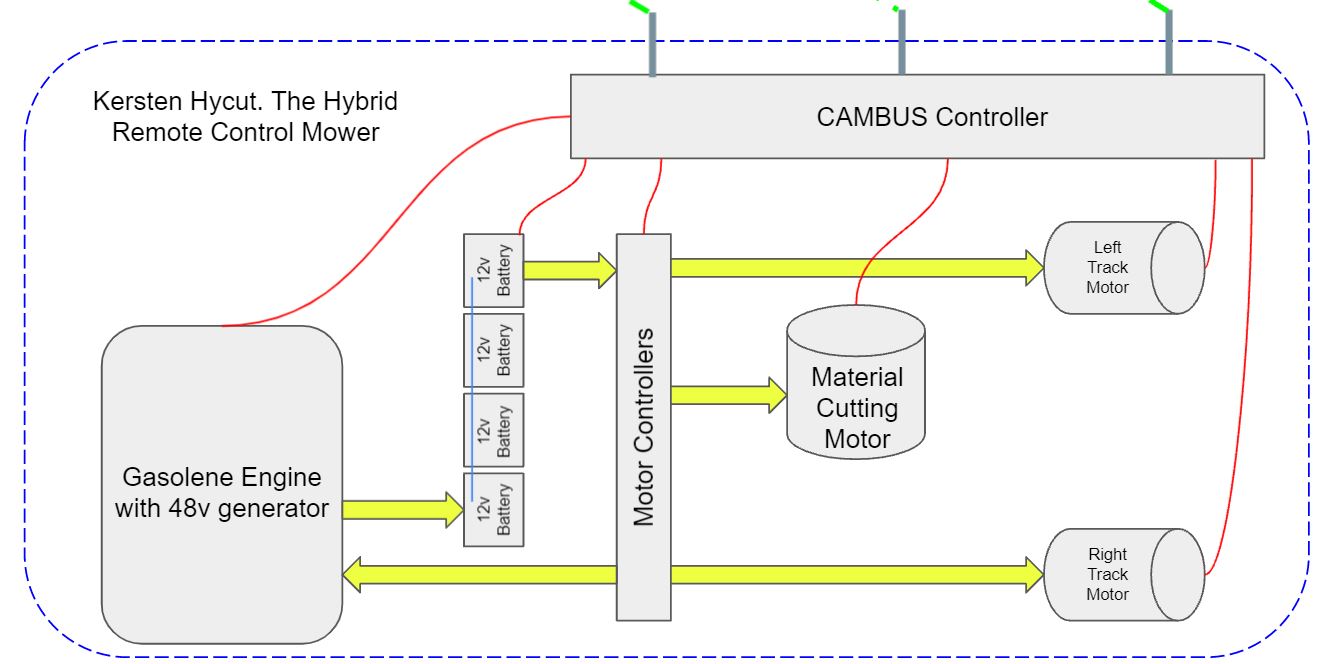

The 48v DC drive system provides power to the blades and to the drive tracks.

The mowing machine may be driven up to 200 metres using battery power alone.

The onboard 48v generator simply charges the battery bank to maintain their charge level.

The generator only delivers the power the mower requires. No more and no less.

The 48v battery pack uses readily available industry standard lead-acid type batteries.

The batteries are secured to the mower with straps and feature robust plastic covers which provide added protection.

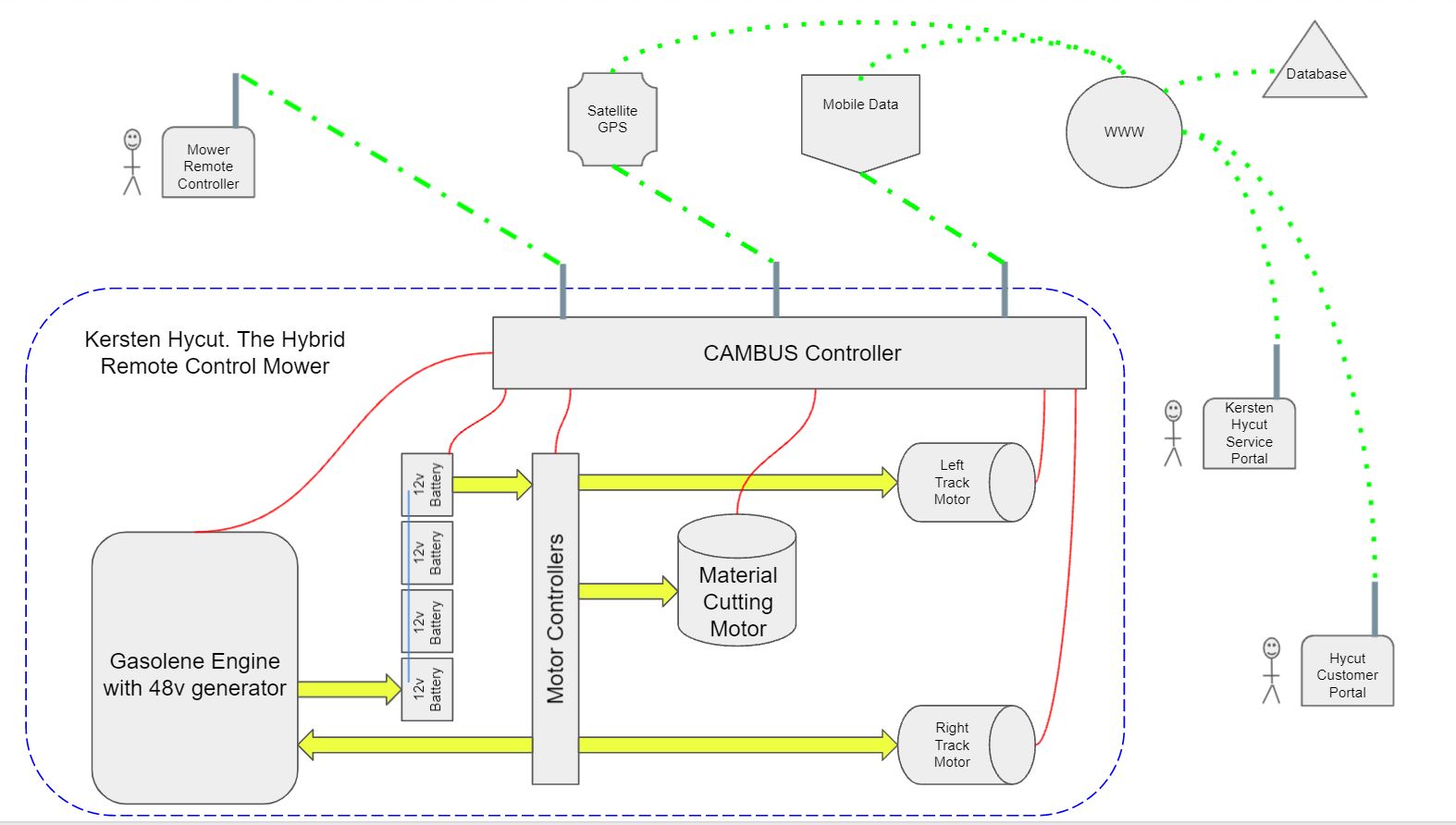

The Hycut mower features a CAM (Controller Area Network) bus control system commonly found in the automotive industry. This CAM bus system enables the key components of the Hycut drive system to communicate with each other.

6 Controllers are connected by the CAM bus system which monitor and control the

- Batteries

- Mower Motor

- Left Drive Motor

- Right Drive Motor

- 48v Generator

- 23hp Briggs and Stratton engine

This system is able to maintain an optimum cutting speed and regulate that speed according to any conditions which may be encountered.

For example, If, due to a heavy patch of material, the CAN bus system detects a reduction in the blade speed on the material cutting motor, (these parameters are adjustable) then the system will automatically reduce the forward speed of the mower to prevent the blade tip speed from reducing further and allow it to recover.

This process requires no intervention from the operator.

The CAM bus controller is, in turn, connected to the

- Remote control radio transmitter

- Satellite tracking system

- And, through mobile data, to the internet and a database

- And finally to service portals accessible by simple web browsers

What does all this technology mean to the customer?

- Considerable fuel savings. Tests have shown that the Kersten Hycut hybrid mower will run all day on less than one tank of fuel (up to 10 hours). This means refueling while the machine is on site may be avoided. Running costs are reduced.

- Increased sensitive control of the mower by the operator makes it a lot easier to use. The steering and drive controls are almost instant. The mower operates the same in cold, hot, wet, dry conditions. The is no time delay waiting for the engine to catch up with a power requirement. The batteries are providing this instant power, not the engine.

- Less wear to drive lines. The mower cutting system features robust steel rotors which require to be started and stopped. These rotors are driven by a belt system. The belt is a useful protection device against system damage by sudden impact. It is common for mower belts to experience excessive wear due to the sudden engagement and disengagement of the steel rotors and blades. The Kersten Hycut mower control system starts and stops these rotors gently. The electric drive allows the speed to be ramped up progressively completely eliminating belt slippage under these conditions.

- Less down time. The CAM bus system is constantly communicating information. The mower has been programmed to automatically trigger events should a specific set of circumstances exist. This information is constantly uploaded via a data link to a database and recorded. This information may be accessed a anytime to provide service support for both preventive and remedial maintenance. Fault codes are signalled on both the operators remote control radio transmitter and a browser based web page. This link is two way so that software upgrades may be executed on the mower remotely.

- Full transparency. The mower historic and current position, state, speed, work area, angle of operation and service record are visible on the web portal at all times.

- Safety. The mower may be safely loaded in to a vehicle by battery power alone. Similarly, in the event of engine failure whilst in work, the mower may be returned to an accessible place for service. In the unlikely event of total power failure the Hycut mower is equipped with a transmission braking system. This prevents the mower from being able to "free wheel" down a hill.

- Productivity. The mower can mow just the same in the forwards and reverse direction. The intuitive 2 lever controls reduce learning time for the operator. The intelligent productivity control systems keep the mower running at its optimum level. The almost instant action from control command on the hand held radio transmitter to the action of the mower constantly saves valuable seconds.

- European, locally sourced solution. Many of the main components are sourced from Europe and UK. The Kersten Hycut mower is manufactured in Europe.

- Hybrid power offers significant environmental advantages. All these above advantages are one step closer to a more sustainable environmental solution.

- Easy on the surface. The tracks on the Hycut mower reduce the ground pressure of the mowing operation dramatically. The added feature of being able to mow both forwards and backwards reduces the risk of surface degradation even further. This cutting system is more likely to leave the surface ecology undamaged and intact.

- Future development. The eagle eyed amongst you will notice a 4 bolt DIN plate mounting system located both back and front of the Hycut Mower. We will soon be adding other attachments to the Kersten Hybrid remote control tracked range.....

More information and features on The Kersten Hycut hybrid radio remote control mower may be found here....

https://kerstenuk.com/hycut-hybrid-remote-control-mower-dri8s

Our Gallery can be found here...

Book a demonstration of this exciting technology at your site NOW!

Chris Faulkner

Chris is Managing Director of Kersten UK Ltd Interested in weed control solutions and machinery

No comments yet. Login to start a new discussion Start a new discussion